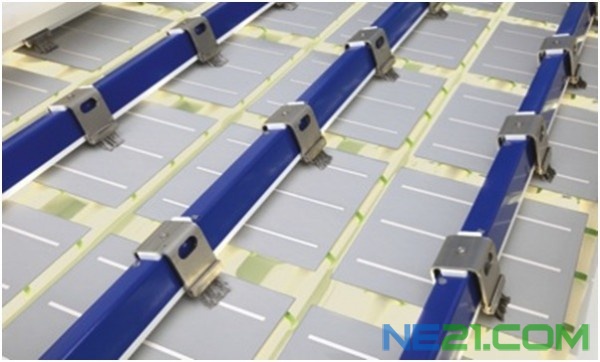

图片来源于:肖特太阳能公司

实现这一目标首要的挑战涉及到铜镍电镀的金属化方法将会阻止铜扩散到硅太阳能电池中,这样将降低电子载流子的寿命,从而降低了太阳能电池的效率。出于这个原因,该项目研究团队已开发出一种电镀镍层,可充当一个扩散屏障,还开发了相应的制造技术,将镍屏障和铜镀应用到太阳能电池中。

该项目团队已经使用RENA公司的新型“单面电池片金属喷镀”(InCellPlate)技术进行制造太阳能电池。这些太阳能电池将用于制造测试模块,以便它们在可靠性测试中验证它们长期的稳定性。此外,项目团队正在将这些开发成果转化到单晶硅太阳能电池中,预计电池效率将超过19%。

Las VeGaS方法除了降低了使用原材料铜的成本还提供了另外一个好处:电镀层是环保的,因为它们无需铅和溶剂,符合欧盟限制使用有害物质指令,该指令限制了使用电气和电子设备中有害物质。现在,太阳能电池已经不再需要使用大量昂贵的银浆,只需一个非常薄的电镀银层焊接电池板到铜镀层,这样,至少降低了95%的银消耗。

Copper replaces silver: multicrystalline solar cell with low cost metal contacts achieves 18 percent efficiency

Nov 28th, 2011

A multicrystalline wafer from SCHOTT Solar AG that features standard screen-printed backside metallization serves as the basis. The goal of the Las VeGaS project is to largely replace the silver contacts that are commonly used on the front side of solar cells with less expensive nickel-copper plating. This would lower the manufacturing costs of front side metallization by more than half. SCHOTT Solar is working together with RENA GmbH and CiS Forschungsinstitut für Mikrosensorik und Photovoltaik GmbH in order to achieve this.

The special challenge involved in metalizing with nickel-copper plating is to prevent diffusion of the copper into the silicon solar cell, as this would reduce the carrier lifetime of the electrons and thus reduce the efficiency of the cell. For this reason, the project team has developed an electroplated nickel layer that serves as a diffusion barrier as well as the appropriate manufacturing techniques for applying both then nickel barrier and the copper contacts to the cell.

The project team has used the new “InCellPlate” technology of RENA to manufacture rather promising prototypes on standard industrial tools. These solar cells will now be used to fabricate test modules so that they can demonstrate their long-term stability in reliability tests. Furthermore, the project team is working on transfering these development successes to monocrystalline cells. Efficiency that exceeds 19 percent are expected.

The Las VeGaS method offers yet another advantage besides the lower costs for the raw material copper: the electroplated layers are environmentally friendly because they are free from both lead and solvents and thus meet the requirements of the European Union’s RoHS Directive. This places restrictions on the use of hazardous substances in electrical and electronic devices. It is now no longer necessary to use large amounts of expensive silver paste, because only a very thin electroplated silver layer is needed to solder the cells to the copper tabs to make a module. This, in turn, lowers the consumption of silver by at least 95 percent.

索比光伏网 https://news.solarbe.com/201111/30/263666.html